RFID and barcode technology complement each other in that if an RFID tag can’t be read, a bar code can provide backup. These two technologies can be the best option for your business if you clearly understand the requirements around cost, security, durability, and implementation of the system. However, these two technologies are different and the advantages accrued in using RFID technology have outweighed those of the bar code technology. Here is why;

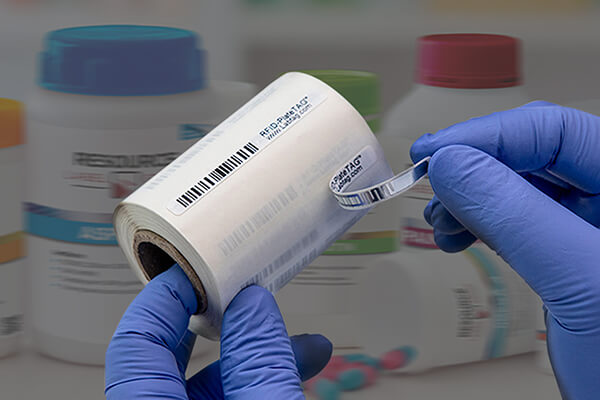

RFID technology is a better choice than barcoding because it is available in three main types; low frequency (LF), high frequency (HF), and ultra-high frequency (UHF). Where LF is used for animal tracking and access control. These RFID tags work best because they are more durable than a barcode. Also, a barcode can become damaged and unreadable with exposure to sun and rain, therefore, it is not ideal for long-term monitoring. ID badges with barcodes don’t offer much security and they can be easily duplicated with a copier. HF RFID is used in quality control of medical supplies and in libraries. An RFID reader can immediately recognize the discrepancy in the library when returning books. UHF RFID is used in large distribution centers and warehouses to track and identify multiple items at once. In the right conditions, UHF offers a much longer read range of up to 30 feet. Therefore, when it comes to security, durability, and efficiency RFID technology has clear advantages over barcodes.

In retail, an RFID reader can read tags from a distance, therefore, typical checkout queues can be eliminated. This saves the customers a lot of hassle and time at the checkout. RFID tags can be reused and reprogrammed. The data collected can be further analyzed to detect demand variation and buying patterns.

Barcode scanning requires a line of sight to access each barcode and it can be used to scan one item at a time. RFID tags don’t require this, therefore, multiple tags can be detected and read remotely and simultaneously. RFID technology not only eliminates the possibility of human error but also streamlines and automates asset scanning. This allows manufacturers to maintain an accurate inventory of all tagged assets, and account for current assets and future supply chain or equipment needs.

RFID technology uniquely identifies items while barcode identifies item type and group. RFID has both read/ write capabilities while barcode is capable of read-only.

Conclusion

More industries and companies are now investing in RFID technology and as a result, the technology is becoming more cost-effective than ever for solving real-world business challenges. Due to the popularity of RFID, soon it may replace barcodes especially, in the supply chain sector. RFID plays a major role in tightening inventory and shipping logistics along the entire chain. Throughout the supply chain, retailer demand is currently leading in the adoption of RFID technology because of the return on investment (ROI). RFID systems are more expensive and they require more setup than barcodes even though they are much more efficient for scanning a large number of items. RFID is a fully automated alternative to barcode scanning that has seen large-scale growth in adoption rates.

Nexqo is a professional RFID hardware provider with more than 10 years of experience in the RFID industry. Click here to learn how RFID label works.

You can also click here to learn more about the products that you can use in your project. If you are not sure, welcome to contact our sales experts any time.