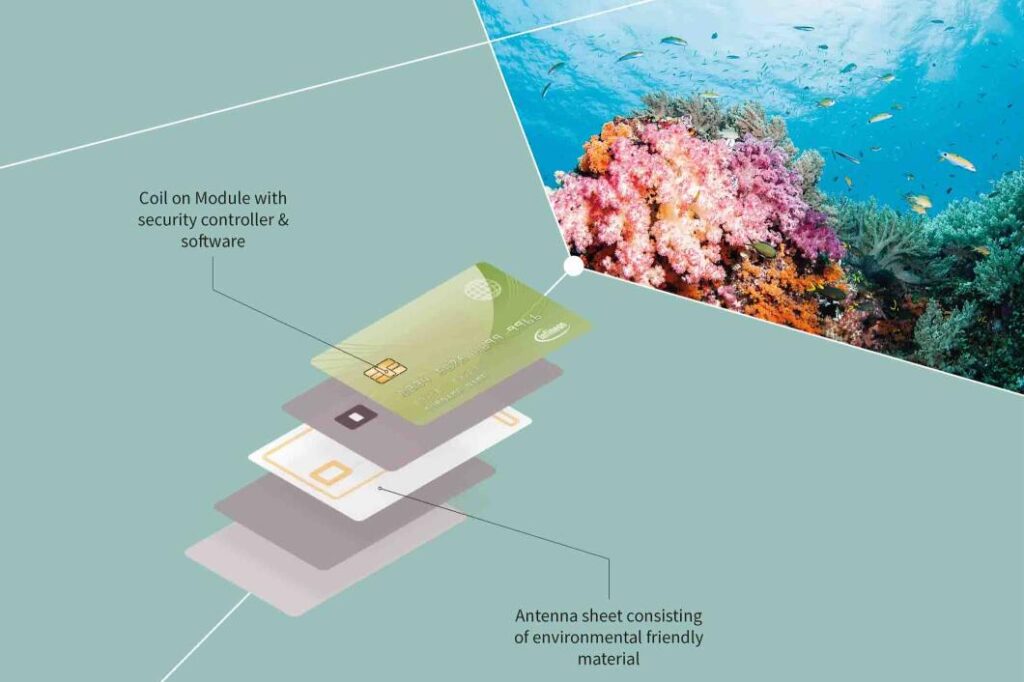

Contactless payment innovations from Infineon Technologies AG (FSE: IFX / OTCQX: IFNNY) contribute to a more sustainable use of resources. To support the payment industry’s move towards the use of more environmentally friendly materials for smart card manufacturing, Infineon is now offering a complete, single-source solution that is easily adaptable to different projects and market requirements. SECORA™ Pay with Coil-on-Module (CoM) package comes with a newly developed antenna, specifically designed for cards made from recycled ocean-bound plastic or wood. It is the industry-wide thinnest payment module with a copper wire antenna, which allows cost-efficient card manufacturing for mass deployment.

“Infineon’s Coil on Module technology is one of the most important innovations for contactless and dual interface payment cards,” said Bjoern Scharfen, who heads the product line Payment & Ticketing Solutions at Infineon. Communication between chip module and card antenna is based on a radio frequency (RF) link, no electrical connection is required. “By using CoM, our chip solutions can be easily integrated into contactless cards made of different materials. Manufacturers can flexibly and cost-effectively change their card designs and offer consumers sustainable, long-lasting products.”

CPI Card Group Inc., a payment technology company and leading provider of credit, debit and prepaid solutions, is already deploying Infineon’s SECORA Pay solution for its new range of eco-friendly plastic cards. “Using the Infineon SECORA Pay solution enabled CPI to bring Second Wave®, our payment card that features a core made of recovered ocean-bound plastic to market quickly. The combination of inductive coupling antennas and chips made scaling this sustainable eco-focused payment card an efficient process”, said Guy DiMaggio from CPI.

Advantages of CoM technology

Environmentally friendly materials such as wood, Polylactid (PLA) or recycled plastic are more challenging to work with compared to PVC, especially when it comes to the card manufacturing processes such as lamination and printing. These have been standardized by the card industry for decades. Infineon’s SECORA Pay solutions use inductive coupling to connect the chip module with the card antenna, which results in a number of advantages for card manufacturers and users.

The payment chip modules have a thickness of only 0.32 mm and are thus up to 50 percent thinner and up to 70 percent lighter compared to other solutions available in the market. Consequently, the CoM module provides higher flexibility concerning card construction while the new antenna design based on state-of-art copper wire is easier to embed into all known inlay sheet materials including recycled ocean-bound plastic. Moreover, there is also no need for additional adhesive elements during the card lamination process.

Finally, CoM technology makes cards more robust and helps to meet the increasing demand for contactless solutions: with CoM, contactless cards can be produced on standard equipment for contact-based cards without making new investments in specific machinery.

Worldwide, cards are the product of choice when it comes to contactless payments. Market research firm ABI Research expects dual interface card shipments to reach 2.2 billion pieces in 2020 (Payment and Banking Card Secure IC Technologies, August 2019). To protect natural resources and to increase environmental sustainability, leading industry players are therefore launching more ecofriendly programs like the Greener Payments Partnership (GPP) program by MasterCard.

Availability

SECORA PAY is available in volume quantities.

Learn what material Nexqo can provide to combine with SECORA Pay solutions here.

This article was first published on https://www.infineon.com/cms/en/about-infineon/press/market-news/2020/INFCSS202011-021.html

.png)