RFID Inlay

RFID pre-laminated, also called RFID inlay, Middleware, is the core for making RFID card.

Nexqo provides all three frequencies RFID inlays (LF, HF and UHF) to fit different client’s requirements.

There are 2 methods to make RFID inlay

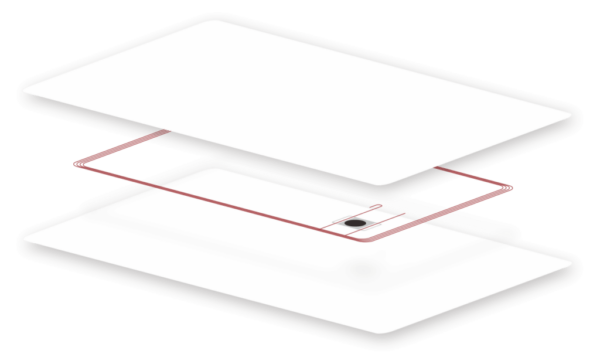

1. Directly laminate

RFID chips and antenna are laminated between 2 PVC sheets directly

Features:

Low cost

Easily processing

Surface is not flat especially the chip position will be bossed.

2. Hollow-out and laminate

Hollow out a hole in the RFID chip position on the PVC sheet, and laminate with another 2 PVC sheets in the front and back side respectively

Features:

Higher cost

More complicated operating

Flat surface that if operated properly, the RFID chip couldn’t be seen from the card surface.

Nexqo uses method 2, hallow-out and laminate, to make all our RFID inlays and cards.

Manufacturing flow

Punching – Top thread – Paster – Butt joint – Detection – Lamination – Test – Craft

Frequency:

LF 125 KHz

HF 13.56 MHz

UHF 840-960 MHz

What we call a good RFID inlay?

Qualified base material

Smooth surface

Ductile and stretching resistance

Every single chip works

Little imprint allowed after breaking test

At least one angle of accurate 90°

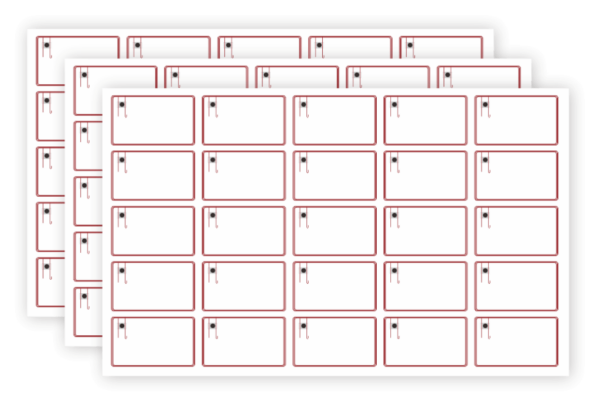

Nexqo provides various layouts of RFID inlay, such as 5*5, 3*8, 6*8

5*5

3*8

6*8

8*10 is also available upon request.

.png)