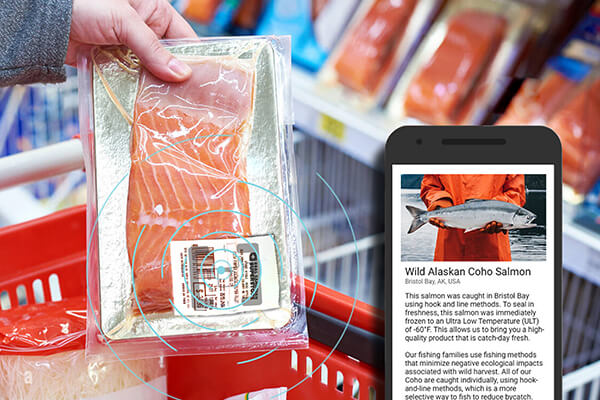

A food traceability system records all information including; processing, growing, breeding, selling, and transporting. To make this system work, every role in the food supply chain must record every producing data and mark it on the package. This system helps to improve food safety. Combining the food traceability system with RFID technology helps to cover the entire food supply chain. Traceability is essential in every supply chain of the food and beverage industry. Therefore, implementing RFID technology saves time in tracking the inventory.

How does it work?

To uniquely identify each food item during packaging, an RFID tag is tagged on the item. After production, a worker with an RFID antenna and reader can walk through the warehouse to complete inventory, when all the items have been packed onto their shelves or pallets and are awaiting shipment. Therefore, you don’t have to worry about human error from manual data entry as the RFID system automatically collects the data about each item. The RFID reader sends the information to the computer and the information is automatically stored in the system. Also, this makes it easy to know when a specific product leaves the warehouse. Achieving traceability with RFID enables you to get key data such as; production or packaging batches, a record of conditions such as temperature or humidity, best-before dates, variable weights, gross, and net weights.

Some fresh fruits and vegetables and fresh products like fish and meat have a high price point and a limited shelf life, therefore, managing them with RFID could prove hugely beneficial. The tag senses temperature and integrates it over time to determine the product’s shelf life which can be communicated to a reader. The tags have an optional visual display indicator (green, yellow, and red) that provides the status of the item (i.e green for fresh and red for unsafe). Also, the RFID system can be used to ensure meat, dairy products, and fruits remain within a safe temperature range during storage and transportation. Combining RFID and temperature logging tags provides the processors with a means of complying with Hazard Analysis and Critical Control Point (HACCP) requirements.

Benefits of RFID in food traceability

- Capturing data during processing.

- Shipments to your customers are guaranteed.

- Identifying codes, dates, and supplier batches upon reception.

- Avoid out-of-date or obsolete stock with proper inventory alert management.

- Full visibility of the productivity.

- Labeling packages according to traceability regulations.

- Improved packaging recirculation.

- Greater customer satisfaction.

Conclusion

RFID technology can read tags through the product even if the product is dense or if inventory in the warehouse is stored close together. RFID systems reduce the reliance on manual processes. The efficiencies gained through using RFID can fuel evolving food distribution models. RFID tags are a more affordable solution for food products because the price of these tags has dropped dramatically. More advanced tags are available and they can work on both liquid and metal products. RFID tags are durable and they can survive low and high temperatures, therefore, they are suitable for all types of food packaging.

Nexqo is a professional RFID hardware provider with more than 10 years of experience in the RFID industry. Click here to learn how the RFID label works.

You can also click here to learn more about the products that you can use in your project. If you are not sure, welcome to contact our sales experts any time.

.png)