The sample clothing warehouse of clothing companies generally stores samples for 3 quarters, and each quarter has new samples. Only outsourcing samples will be stored in the ERP. The remaining samples are not accurate and quantifiable. The data reports can no longer meet the new development of sample management, which brings new challenges to the sample management of the clothing industry.

As the application of RFID technology becomes more and more widespread, the scale of production and technological advancement makes the cost of chips lower and lower, which in turn promotes the wider application of this technology. The use of RFID technology can realize functions such as lifetime tracking, efficiency improvement and intelligent anti-theft, which completely solves the problems faced by current sample management.

No.1 label binding product, effective anti-counterfeiting

In the production process of clothing, the important attributes of a single piece of clothing, such as: name, grade, article number, model, fabric, lining, washing method, execution standard, product number, inspector number, etc. are written into the corresponding RFID electronic tag, then attach the electronic tag to the clothing.

Electronic tags can be attached by means of: embedded in clothing, made of nameplates or tags, or of recycled anti-theft hard tags. Each piece of clothing is given a unique electronic label that is difficult to counterfeit, which can be effectively prevented counterfeiting.

No.2 high-quality logistics, optimize supply chain management

When delivering goods in the warehouse, worker quickly scan the goods with RFID reader, check the scan results and the delivery notice, generate and print the shipment list of each box of goods, and record each RFID tag information such as shipping time, cargo destination, agent number, etc.

Realizing the tracking of lifetime of goods and the standardization of clothing logistics operations, which can shorten the operation process and time, and reduce the labor cost.At the same time, using RFID technology can minimize the error rate of delivery. Delivery errors mainly refers to the shortage of original boxes and wrong box packaging.

No.3 warehouse high efficiency collection, delivery, inventory checking

One of the most important tasks in the sample clothing warehouse is to ensure that the book quantity being consistent with the physical quantity. When the warehouse staff picks or checks inventory, the RFID bar reader can be used to quickly pick the target goods according to the order, avoiding wrong picking or missing inspection. There is no need to perform one-by-one in order to achieve efficient inventory checking. The operation is simple and easy to learn, and it is very convenient to realize the accuracy of goods receipt records and the automation of delivery and distribution.

At the same time, it can record the information of the sample clothing entering and returning to everyone through the sample clothing management system. It can perform daily and monthly data statistics, and dock with the ERP system to improve the sample clothing management system. Using data and cloud platforms promotes transparency of sample information.

No.4 stock-outs alarm, timely replenishment

Through the RFID sample clothing management system, when a product shortage occurs in the warehouse, not only the alarm can be automatically prompted, but also the details of product composition such as models, colors, and sizes can be subdivided.

No.5 Statistics of unsold products, maximizing benefits

The inventory backlog is a very headache thing. Through the RFID sample management system, it can calculate the duration time of each product (divided into models, colors, and sizes). After the season, managers can quickly make price reduction decision to accelerate product sales and capital turnover.

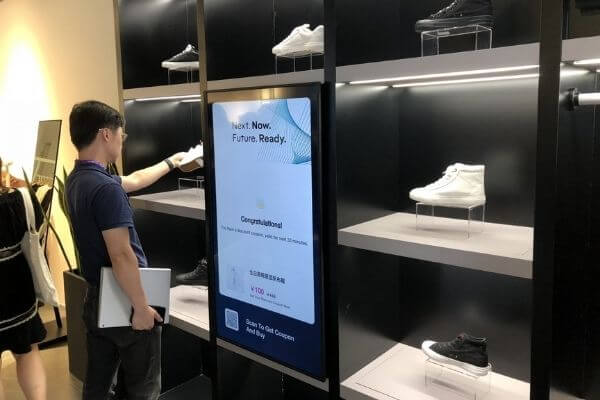

No.6 Intelligent anti-theft, quickly stop loss

The anti-theft management system integrates a high-performance high-power reader and AM anti-theft system, which can quickly identify UHF RFID tags in any direction in the sensing area of the device; the longest reading range can reach 200CM. It can better solve the problem of shoplifting. Utilizing RFID access control system, real-time monitoring the sample clothing information in the warehouse, the stolen product can be found immediately, avoiding rework afterwards, and reducing the cost of stolen product.

.png)